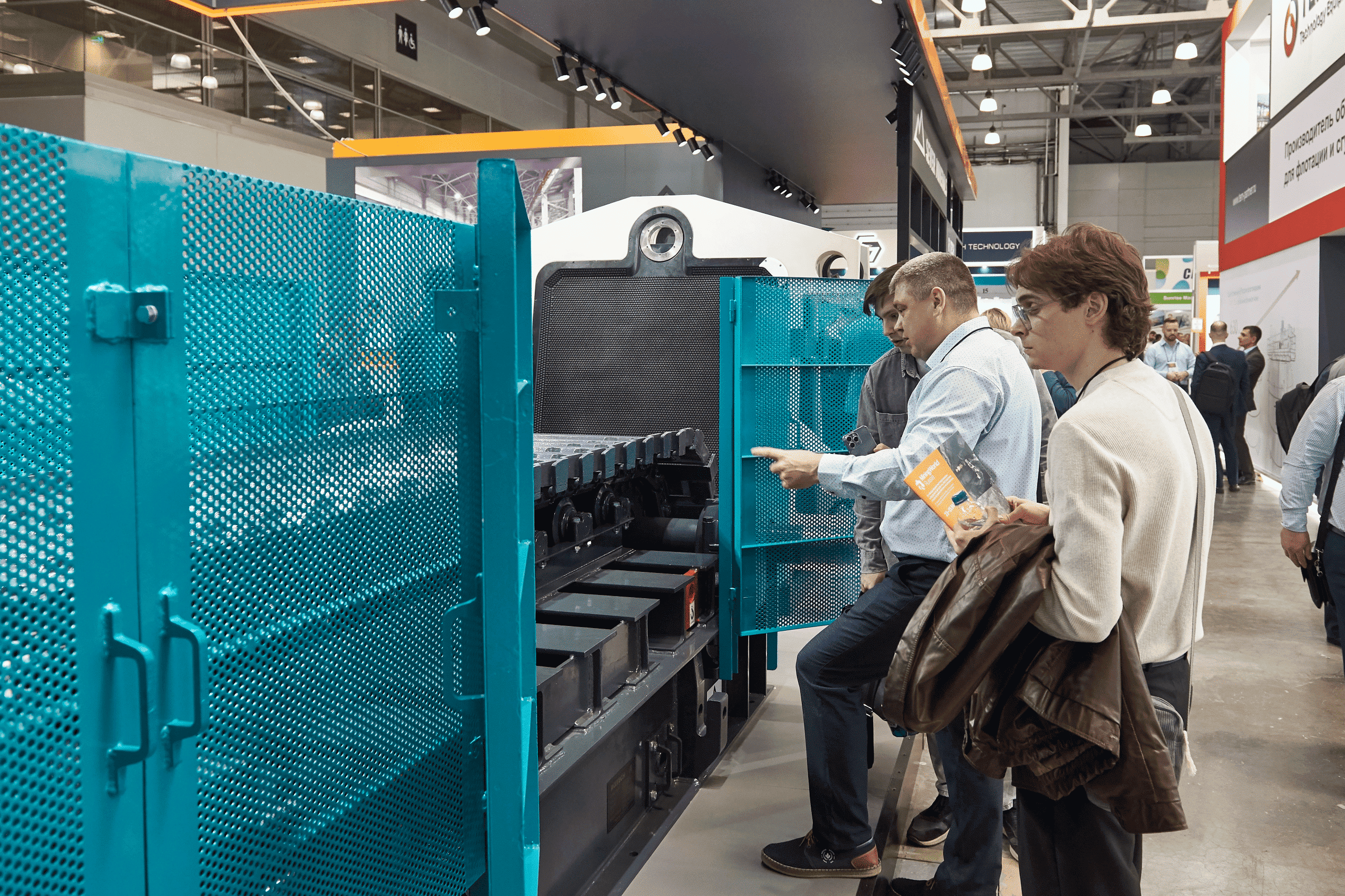

Mill Pumps RT-MC

RT-MC series mill pumps are a series of horizontal mill pumps designed for pumping large solids in dense abrasive slurries and is an optimal combination of strength, durability, excellent hydraulics of flow parts and materials.

This series is available in three modifications:

- The MCR model is a rubber-lined double casing pump;

- The MCU model is a single-casing metal pump;

- The MCM model is a metal-lined double casing pump;

- Use of special alloys to increase wear resistance;

- Use of various seals, including those that do not require water supply under pressure;

- Can be equipped with a wide range of bearing units with both grease and oil bath.

- It is possible to complete with a sliding frame.

APPLICATION AREAS

PROCESSES

- Pumping of grinding products

- Transport of wet beneficiation products

- Slurry Pumping in Gravel Excavation

- Feeding of coarse coal to hydrocyclones

- Transport of highly abrasive and corrosive media

- Circulation of a dense medium in the process of coal preparation

- Tailings Products Handling

Advantages

1

Extended service life

The flow part, which is 50% thicker than RT-AH, extends the life of the wear parts.

2

Low wear rate

The impeller with profiled blades, which is 30% larger in diameter than the RT-AN, reduces rotational speed and slows wear.

3

Uniform wear

Simultaneous adjustment of the front and rear armored disc ensures uniform wear and extends the service life of the flow part.

4

Easy maintenance

The split cover and pump housing provide easy access to the

impeller and front armored disc for their replacement. The sliding frame modification greatly simplifies and speeds up this process.