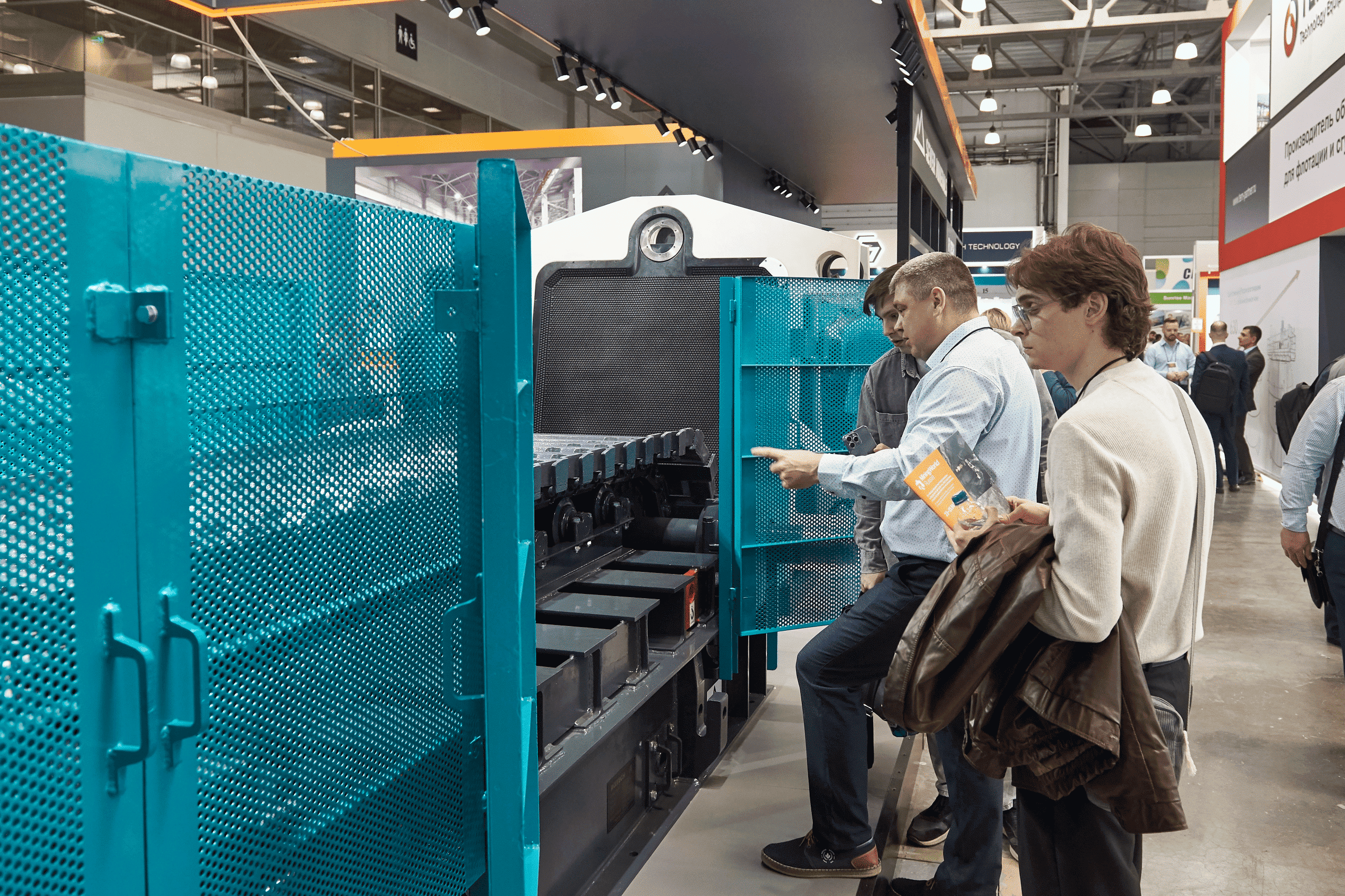

CHRON rubber-to-metal lining

CHRON® is a rubber-metal lightweight lining with a simplified fastening system.

It is designed for mills with a large bowl diameter, in which it is possible to use modern manipulators for relining mills.

The lining is made of wear-resistant rubber on a steel substrate with inserts made of Hardox rolled steel, cast iron or chromium-molybdenum steel.

Our specialists will analyze and select the alloy based on the tasks and operating conditions of the equipment.

Advantages

1

REDUCING THE NUMBER OF ELEMENTS

CHRON® contains 2-3 times fewer elements compared to metal lining, which reduces the time for scheduled repairs by up to 35%.

2

SIMPLIFIED INSTALLATION

The liner bolts are installed on the outside of the mill, which simplifies the installation process.

3

STAND-ALONE INSTALLATION

The manipulator operator can carry out the installation independently, eliminating the need for an assembly team inside the mill.

4

ENHANCED SECURITY

The process of dismantling and replacing the linings is carried out with a high level of safety.

5

REDUCED WORKLOAD

Reduced loads on mill drive groups and lower energy costs contribute to higher equipment utilization (CRO).

6

EXTENDED LIFESPAN

The use of the optimal alloy and profile adapted to the specific operating conditions significantly extends the service life of the lining.

7

NOISE REDUCTION

Vibration damping by rubber lining elements helps to reduce noise levels during mill operation.