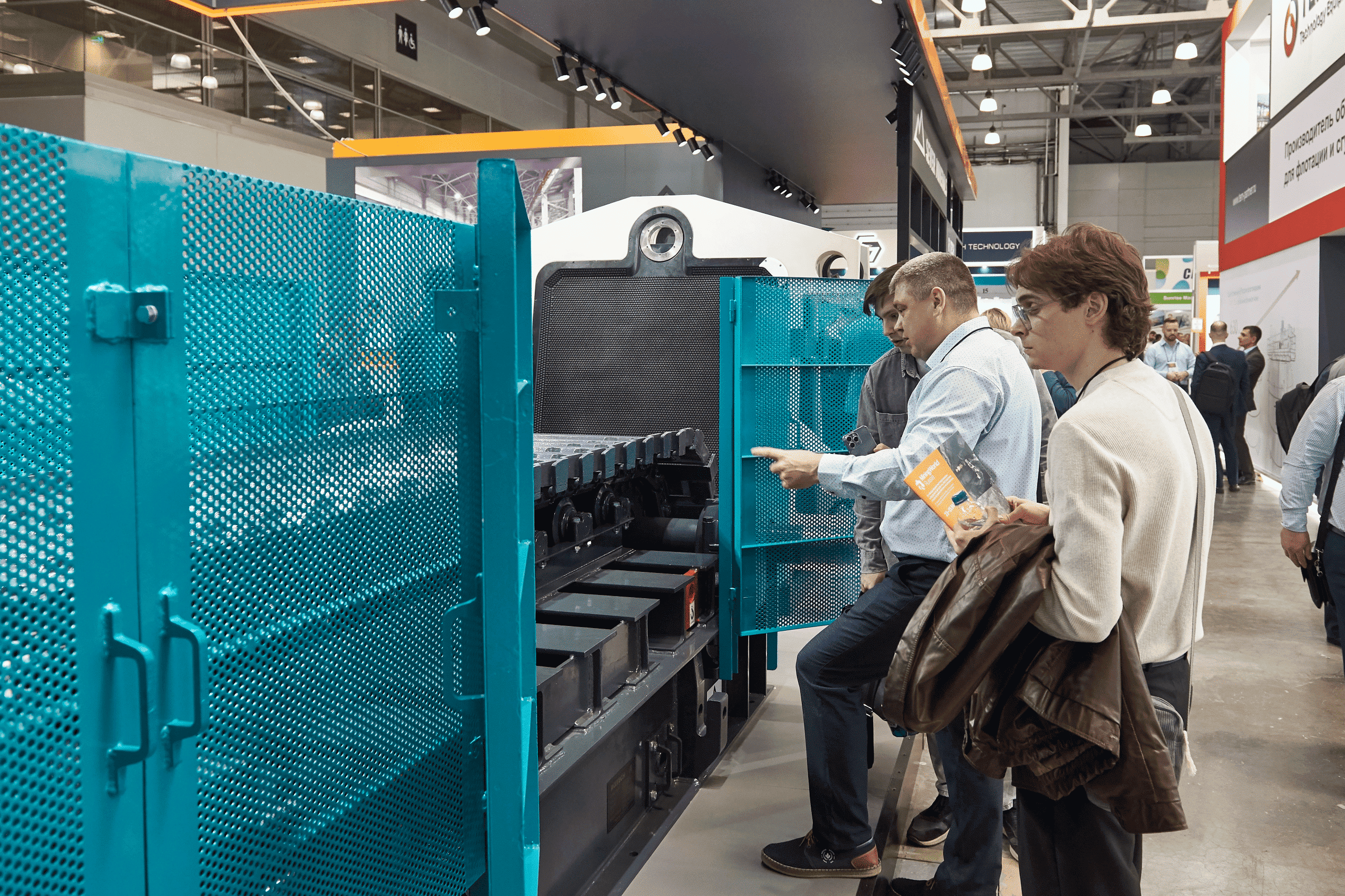

Metal lining

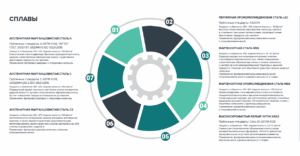

ROITECH metal lining is ideal for different types of mills, providing a choice of optimal design and alloy depending on the specific application. When determining the chemical composition and heat treatment requirements, key parameters such as the current capacity of the equipment, the frequency of element changes, the dimensions of the mill, the type of grinding and grinding media used, as well as the configuration and thickness of the lining, are taken into account.

Advantages

1

INDIVIDUAL SELECTION OF ALLOY

ROITECH experts carry out a detailed analysis of the operating data of the equipment and the frequency of element changes, taking into account parameters such as the dimensions of the mill, the type of grinding, the grinding media used, as well as the configuration and thickness of the lining. This allows you to select the optimal grade that meets the specific requirements of your specific production process.

2

PRODUCTION CAPABILITIES

In the process of manufacturing mill linings, modern alloys are used, which provides high strength and wear resistance. ROITECH has the capability to produce lining elements of various sizes and weights, which allows us to adapt to customer requirements.

3

MATERIAL COMBINATION

The use of different materials in the lining design significantly increases the service life of the elements, which contributes to reducing maintenance costs and improving the overall efficiency of the equipment.

4

HIGH VARIABILITY IN THE DESIGN AND MANUFACTURE OF ELEMENTS

Adaptable and customizable lining elements to meet specific requirements and operating conditions.